Top 7 Flexo Printing Plates Manufacturers in India

How To Choose a Flexographic Printing Plate (In 2022)?

June 25, 2022Flexo printing plates are used to print on the flexible packaging materials like poly bags, non-woven bags, pouches, paper cups, etc. Flexography is a modern version of letter press and is mostly used for printing on non-porous substrates. Flexo printing plates are made up of photopolymer resin and act as a carrier medium during the transfer of ink to the desired surface.

Flexo Printing Plates are the lifeblood of any production house. Without these, it would be impossible to print attractive, high quality images at the speed that we all desire. These printing plates are made specifically for flexographic printing and come in a variety of different models and sizes.

What is a Flexographic Printing Plate?

Images are printed on a unique surface known as a flexographic printing plate. Paper and plastic are only two of the many materials that may be used to create flexographic printing plates. They are created by putting ink on the plate, pressing it against paper or another picture to create an image, and then drying it. They are tiny sheets of rubber that may be used to make many copies of your artwork and hold your design. You may select the one that is perfect for your project because they come in a variety of sizes and thicknesses!

Prints on paper are produced using lithographic printing plates, such as flexographic printing plates. They are composed of a stiff surface that may be inked up and imprinted with pictures that have been transferred from a plate; when placed up against paper, they respond by producing a negative image.

How do Flexo Plates Work?

Flexo printing plates work by making an image using two different colored inks. One of these inks is used to print the image on the paper while the other is used to create a negative image. The positive image is then transferred onto an aluminum plate which can be used again to create a second negative image.

The Process of Flexo Printing is as follows:

Step 1 –

The first step involves placing two different colored inks on top of each other so that they form a single layer. This layer will then be placed over a piece of paper with a textured surface. The ink that has been placed on top should be thicker than the one below it so that when pressed against the paper, it creates a raised pattern.

Step 2 –

Next, another piece of paper is pressed against this first sheet which has created an impression in its surface. This new sheet will then be removed and paired with another piece of paper with a smooth surface for creating another impression on it. Once both sheets have been created, they are placed on top of each other with their impressions lined up perfectly with one another so that they create one continuous image across both sheets of paper at once!

Flexo printing plates manufacturers are the best ones and if you want purchasing high quality of the flexo printing plates then it is very hard for you. Also we can get the top flexo printing plates manufacturers in India and their products are certified by IPC (India) standard also so that your print quality is improved by them.

Now let us have a look at top 7 flexo printing plate manufacturers with their specific business details:

1. KIVI MARKINGS

Due to our year of expertise in UV curable chemistry, KIVI MARKINGS has created novel products for the production of Flexo plates and text plates for rubber stamps (Hand Stamp). They are continually creating different UV curable Photopolymers to offer the best solutions to the corrugation printing industry. KIVI MARKINGS has created its own Base Film Substrate in addition to Liquid Photopolymer.

Base film are excellent candidates for big format printers since we were able to obtain very homogeneous coating with the use of the most recent scanning technology. With any liquid photopolymer on the market, KIVI MARKINGS Super Base Films provide exceptional adherence. They have devoted marketing and technical experts at your disposal to support KIVI MARKINGS’ unique goods.

2. Creative Graphics

Creative Graphics assists companies with our top-notch services to help get the desired look and feel for their products and packages through our creative and production expertise.

We process digital flexo plates for sticky papers, corrugated boxes, polybags, wide web flexo, offset coatings, security printing, dry offset applications, and all packaging flexo printing.

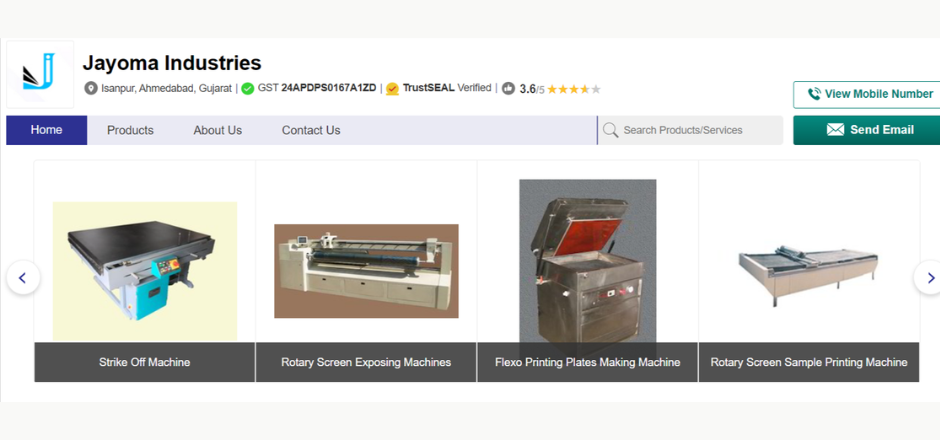

3. Jayoma Industries

JAYOMA INDUSTRIES is a reputable manufacturer and exporter of equipment for creating screens and photopolymer plates.

For the last 20 years, Jayoma Industries has been a manufacturer of rotary and flat-screen equipment for the textile screen printing industry, ceramic screen printing equipment, offset plate producing equipment, and various types of UV exposing and curing equipment.

4. SHAKTI UDYOG LTD

Since its incorporation in 1992, Shakti Udyog has grown to become a dominant force in the Indian Graphic Arts sector. Chennai, India’s major industrial hub, is where Shakti Udyog is headquartered. COMMITMENT: To provide cutting-edge, reasonably priced technology to the industry on a global scale. PHILOSOPHY: Cooperating to give the sector a constructive fresh push. Innovative research & development that results in the release of innovative and cutting-edge goods is supported by professionals committed to service.

5. Innovative Flexotech Pvt. ltd.

Innovative Flexotech Pvt. Ltd. of India is a market leader in photopolymer plate manufacturing and flexo printing press technology, providing goods, solutions, and services under the brand promise of “High Standard Quality, Most Competitive Price, and Superior Service.”

A 25-person, innovative technical team with a head office in Ahmedabad and a manufacturing facility in Viramgam. The business produces photopolymer plate making equipment, flexography plate making equipment, letterpress plate making equipment, water wash flexo plate making equipment, etc…

6. FLEXOGRAPHY INDIA PRESS

In order to provide more than 21 series of products in the Flexography Photo Polymer Plate making system, including the Flexography Solvent Recovery system, Label & Letterpress Photo Polymer Plate Making, & All Flexo series Photopolymer block making Machine, Rubber Stamp Machine & All type of Stamp Making Machine series, FLEXOGRAPHY INDIA PRESS adopts advanced technologies and high-quality material.

7. Friends Engineering Corporation

For the past 45 years, Friends Engineering Overseas Exports has been a producer, exporter, supplier, and service provider of corrugated box plants, printing equipment, and binding equipment. Since 1960, our firm has grown to become one of the top producers of paper converting equipment, paper bag-making machines, and other items. Because we consistently provide the highest standard of quality and highly effective Machines at the most competitive costs, our firm has been able to establish a solid reputation. India’s first company to produce high-quality machines with a range of setups and requirements is us. the full selection of paper conversion equipment.

Conclusion

Flexographic printing is widely used in packaging industries to print on glass and plastic bottles, plastic and metal cans, tubes, aluminum sachets, cosmetic jars, and coat hangers, among many other items. This can help in reducing the cost of manufacturing items as well as reduce environmental hazards caused by the cyanide-based offset process. Consequently, it is no wonder that flexo printing has become one of the most sought-after processes for businesses.

The above-mentioned list of flexo printing plate manufacturers has been prepared after a lot of market surveys and feedback received from various customers. We have created this list to save your time and efforts. Almost all the companies mentioned in this article are ISO certified which ensures the company’s credibility. Kindly go through the details of each company carefully before placing an order to avoid any confusion or disputes later on. If you need service-related flexo printing plates feel free to contact us.

Frequently Ask Questions

Q1:- What is Flexographic printing used for?

A1:- Flexography has been widely used as a quick and economical way of applying simple designs and areas of color to a wide variety of packaging materials, such as paper and plastic containers (including waxed-paper ones), corrugated-cardboard boxes, tape, envelopes, and metal foil.

Q2:- What are digital flexo plates?

A2:-Commonly called flexo, this is a rotary direct printing method that uses rubber relief or photopolymer-based material printing forms. Flexo printing is used in a variety of fields, especially for packaging.

Q3:- What is a flexographic printing press?

A3:-A flexo press uses flexible photopolymer printing plates to imprint images across a wide range of surfaces, making it one of the most efficient methods for large volume requirements. Used widely for labels and packaging – flexo printing is reliable and provides consistently high-quality print results at the same time.