Gravure vs. Flexo Printing: Advantages and Disadvantages

A Step-by-Step Guide to Flexography on How Flexographic Printing Works

June 29, 2022

A Step-By-Step Guide to Letterpress Printing Process ( 2022 Edition)

July 25, 2022In the age of growing consumer demand, marketers and manufacturers are always looking for better ways to deliver products. When it comes to packaging, the choice between flexo printing versus gravure printing may not be an easy one.

Although it’s a widely accepted fact that digital printing is the most cost-effective way to produce high-quality products, there are still times when you might need full-color printed materials that look and feel like they were printed on a press.

If this sounds like something your business needs, then you’re in luck both flexo and gravure printing can give you exactly what you want! However, it’s important to understand how each method works before deciding which one is right for your project.

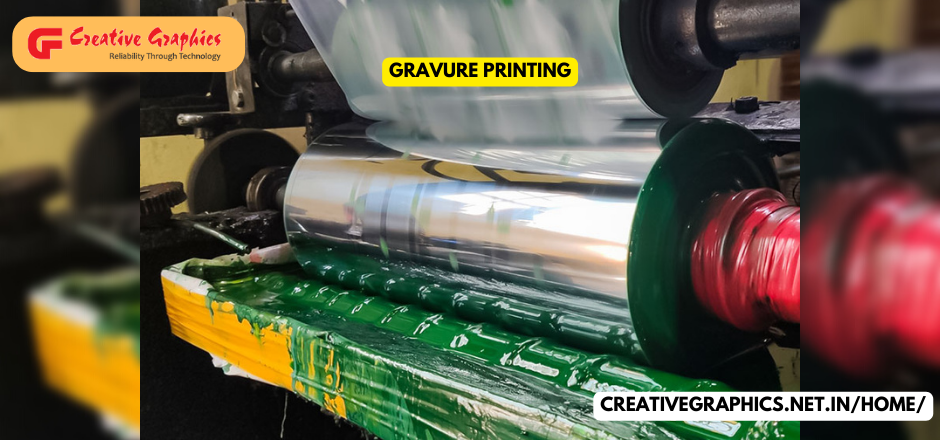

Gravure Printing

Gravure printing sometimes referred to as Rotogravure, is a long-run, fast, and high-quality printing technique. Gravure is an intaglio printing technique similar to engraving in that it creates delicate, detailed pictures.

For CMYK printing, where each color of ink is applied by a separate cylinder with drying phases in between, it works effectively.

Gravure printing is a method of printing that is used to print on a variety of materials such as paper, plastic, metal, and glass.

Gravure machines are used to print the majority of the high-quality packaging labels in use today. These machines are capable of producing high resolutions on products ranging from food packaging to cosmetics.

They work by using a gravure cylinder that has an engraved pattern with tiny ink channels called “grooves” or “rills” etched into its surface; these grooves hold up to ten times more ink than other types of printing presses. The ink is then transferred onto the substrate by pressure rolls that run along each side of these grooves (one side at a time).

Pros of Gravure Printing

- Flexibility:

A relatively wide range of colors can be printed on a gravure press and the quality is high, making it appropriate for short-run printing jobs.

In comparison to flexo printing, which tends to not print as many colors at once and requires different screens depending on what is being printed (some colors are better suited), gravure offers better versatility in terms of its capabilities.

- Durability:

Gravure is known for being extremely long-lasting and durable in terms of print quality it won’t fade or scratch off easily over time as some other methods do.

This makes it ideal for products that need extra protection from environmental factors such as sunlight or heat/cold fluctuations so they’ll last longer without degradation in appearance or quality (e.g., outdoor signs).

- Print quality:

The equipment used in gravure printing produces consistent results, which means you can be sure that your print job will look great every time.

- Easily reproducible

This type of printing can be done quickly without having to worry about any errors occurring during production since there are no moving parts involved as there are with other methods such as screen printing which requires multiple steps before being able to produce copies of your design onto the paper stock.”

Cons of Gravure Printing

Although gravure printing is a great method for printing on smaller runs, the higher cost per unit and longer run lengths make it more expensive to get started.

- Expensive Solution:

Gravure printers are more expensive than other types of printing. This means that if you’re looking for a low-cost solution, gravure probably isn’t the best option for you. However, if you want to create something that’s going to last for years and years, then gravure might be the ideal choice!

- Gravure Printing takes Time and Planning:

The more time that goes into prepping your design and the more work that goes into printing it on your product, the better quality you’ll get from the final product. This means that if you don’t have much time or money (or both), then gravure might not be right for your business model!

- Doesn’t work well with highly detailed images

Gravure printing doesn’t work well with highly detailed images because it creates small dots on the paper.

Flexo Printing

Flexo printing is a high-speed printing method that uses a printing plate and a rubber blanket to apply ink to paper. This method is used to print on packaging, labels, and other products.

Flexo printing can be used with a variety of materials such as metal foils, plastic films, glassine papers, aluminum foils, and laminates. The main advantage of flexographic printing is its ability to print detailed images without any loss in quality.

The most common type of flexo presses is large-format offset presses which use metal plates instead of photopolymers plates like those used by gravure or lithography presses.

However, if you don’t have access to one then there are smaller tabletop versions available that allow you to do small runs at home or at school!

The process begins with a digital image file that is used to create a negative form on the roller. The roller is then inked with a special ink that adheres to the surface of the roller, but not the grooves in between them.

When this flexo roll is pressed against paper or another medium, it transfers its image onto the surface without any ink being deposited into the grooves where it would not show up on your final product!

Pros of Flexo Printing

- Produces High-Quality Images:

Flexo printing produces high-quality images that can be reused multiple times without losing quality or clarity.

- Less expensive:

Flexo printing is less expensive than other types of printing because it uses less ink per print run than other processes do (offset lithography requires more ink because it uses water-based plates instead of plastic ones).

- Use Different Types of Substrates:

Flexo printing can be used on many different types of substrates (like cardboard or plastic), and it doesn’t require special materials like those used by letterpress machines (which use metal plates).

- Great for Short Runs:

If you only need a small number of printed materials, flexo printing may be better than other methods because it’s fast and efficient! Because there’s no setup time involved in this method (other than setting up your press), you can get more done faster than with other methods like offset lithography (OL).

- Recycled Materials:

Because it doesn’t require any chemicals or solvents, flexo-printed products can be made using recycled materials like plastic bottles or cardboard boxes—which means less waste in landfills

Cons of Flexo Printing

- Initial setup may require some time.

Flexographic printing requires a lengthy setup process. This is a result of the entire process being automated. Installing the material, setting the colors on the appropriate plates, using the appropriate plates to wrap the plate cylinders, and setting up the correct cutting die all need human labor. It could take some time.

- Not Suitable for Heavy Stock Products

Flexographic printing is not suitable for heavy stock products since this type of paper can easily tear during the production process. In addition, using heavy stock paper can cause problems during drying as it may take longer for them to dry completely before they can be stacked for shipping purposes.

- Flexography can be costly to use for small works.

Flexographic printing only truly makes sense when you’re performing a medium- to large-volume production since the plates used in this process are so robust. Additionally, bear in mind that you will need to submit a plate for each color if the task requires several colors.

Choose the Print Method that will Best Fit Your Needs.

Flexo printing is typically more cost-effective than gravure since it uses less ink to produce high-quality products. Flexo printing also has the added benefit of being more versatile than gravure because it can print on a variety of substrates and in different shapes and sizes.

When it comes to environmental friendliness, flexo printing has an edge over gravure as well: because flexo requires less ink, there’s less waste afterward; also, because the curing process for flexo doesn’t involve heat (as is true for gravures), there are fewer emissions associated with that part of the process. Flexo tends to last longer than gravures as well—in some cases up to 10 times longer! Finally, flexos tend to be more resistant than gravures when exposed to water or sunlight; they’re also more resistant against chemicals like acids or alkalis (i.e., cleaners).

Conclusion

After reading this article, you should have a better understanding of the differences between gravure and flexo printing. Both methods have their advantages and disadvantages, but it all comes down to what is most important for your business.

If you Looking for a flexo printing solution? We can help!. Creative Graphics is a full-service flexo printer, with a team of experts who can help you find the right set-up for your business.

We specialize in helping companies that need to print small to large runs of labels, packaging, and other products that require high-quality printing. If you’re looking for a reliable flexo printer with a focus on customer service and satisfaction, we’d love to hear from you!. Contact us for more Details.

FAQ’s

Q 1. What distinguishes flexo from rotogravure printing?

Comparing gravure and flexo printing in an image

Flexographic printing processes have irregular print quality restrictions due to poor consistency of print output, but rotogravure technology generates extraordinarily high-quality results quickly. While rotogravure is preferable for longer runs, flexographic printing is superior for short-run tasks.

Q 2. Can you still use gravure printing?

For the commercial manufacture of postcards, periodicals, newspapers, and corrugated cardboard, gravure printing is still commonly utilized (and other packaging materials). When work requires precise, detailed pictures in a fast, high-quality, and long-run printing process, rotogravure is used.

Q 3. Are offset and gravure the same thing?

In web offset, a printing plate is used; in gravure, an ink-carrying cell-encrusted cylinder is used. Gravure is an intaglio printing method, while web offset is an offset printing method (i.e. the cylinder comes into direct contact with the paper and is not offset). The heat from a gas oven dries web offset inks.